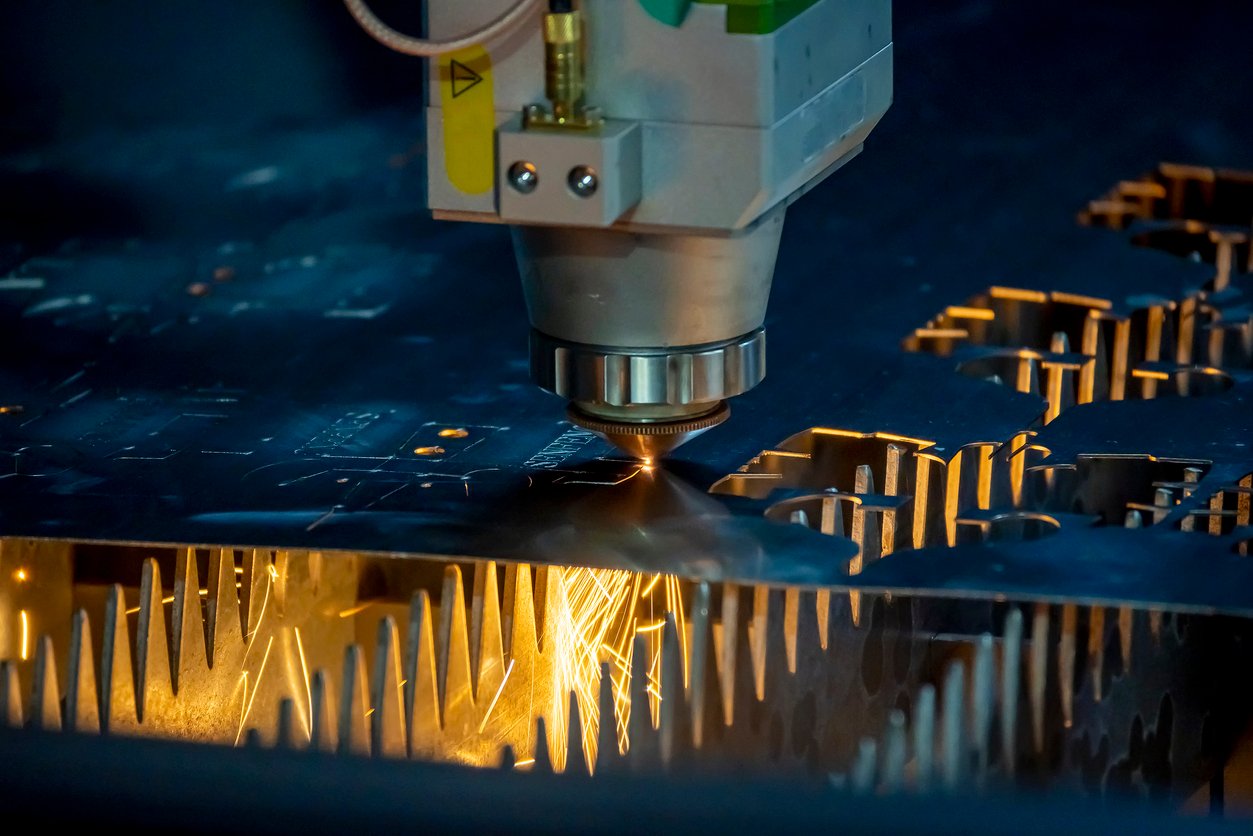

The automotive industry is on the brink of a revolution as laser cutting machines are shaping the future of engineering. With unprecedented accuracy, these high-powered machines can carry out intricate cuts that previously required human labor.

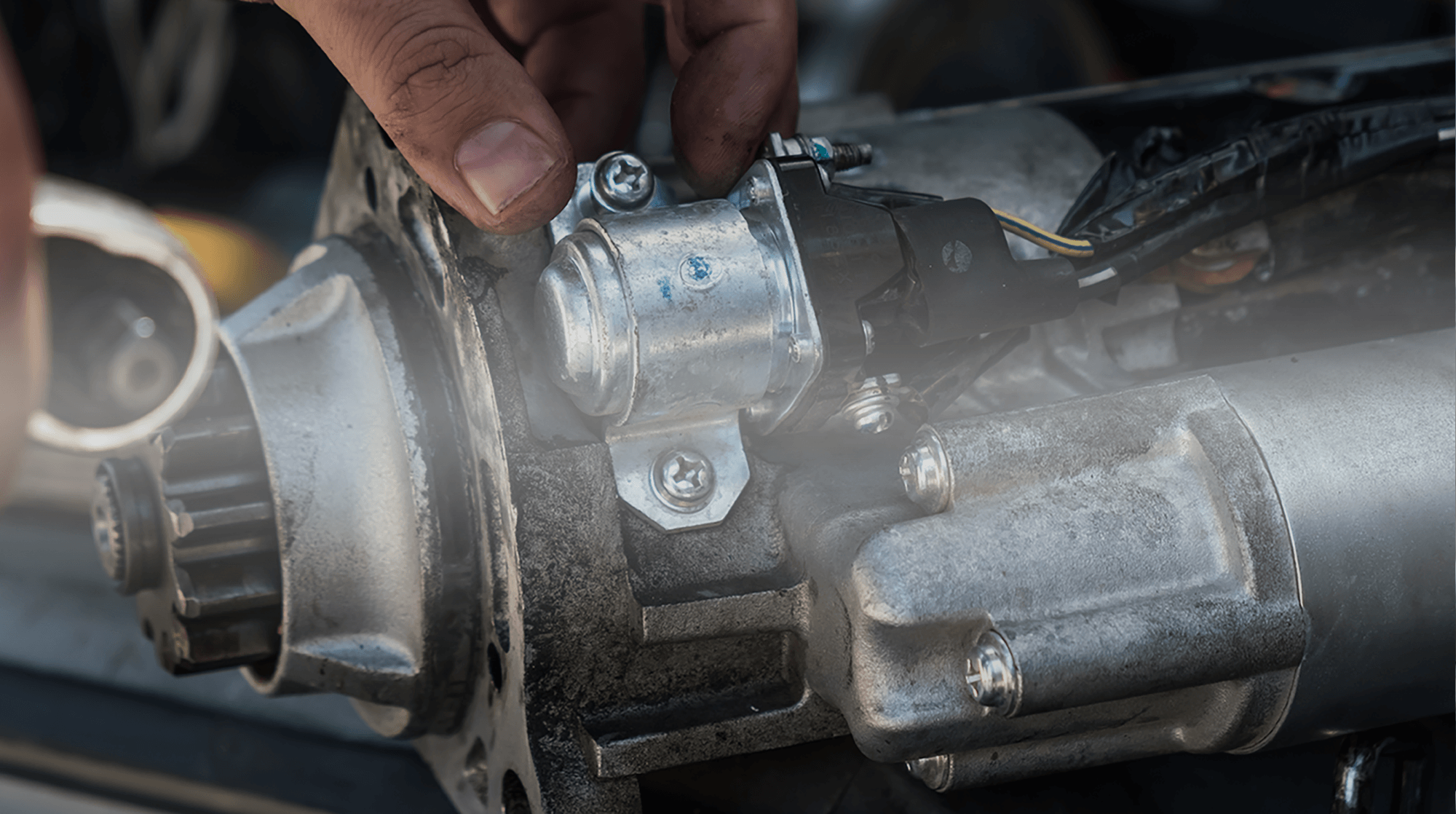

This technology has already made great strides in improving efficiency and productivity across many industries, but its true potential lies within the world of automotive engineering. Laser cutting machines allow engineers to create complex designs with a level of precision never seen before, from intricate parts for engines to beautiful car bodywork.

Its no surprise that this technology is quickly becoming an integral part of modern car manufacturing and design processes. In this article we will explore how laser cutting machines are changing the way cars are designed, manufactured and even raced!

Improved Precision and Efficiency

Laser cutting machines are revolutionizing the automotive engineering sector, enabling unprecedented levels of precision and efficiency when it comes to manufacturing. With laser cutting technology, components can be cut with millimetre accuracy, eliminating the need for costly errors or re-work.

The speed at which these tiny cuts can be made also ensures that production times are reduced significantly compared to traditional techniques. Laser machines provide a greater degree of flexibility too; by quickly changing settings on the machine, parts can be adapted to meet individual customer needs without compromising on quality or time constraints.

This level of precision is not achievable using other methods such as water jetting or grinding and has resulted in a smarter approach to automotive engineering.

Reducing Costs and Waste

The use of laser cutting machines in automotive engineering has revolutionized the industry. By reducing costs and waste, these machines offer a more efficient way to produce car parts.

With state-of-the-art technology, laser cutters create precise cuts with minimal material waste and energy consumption. Engineers can design intricate shapes that were previously impossible to achieve with traditional methods, while also ensuring less scrap is produced.

3D printing techniques are often used alongside laser cutting for complex geometries, which further reduces production costs by eliminating the need for expensive molds or dies. Designers have a greater degree of control over their products; they can easily modify existing designs or quickly create new ones without having to start from scratch each time.

This flexibility enables them to produce better car parts faster than ever before – an invaluable benefit in todays competitive market.

Automating Production Processes

Automating production processes with laser cutting machines is revolutionizing the automotive engineering industry. Laser-cutting technology offers precision and speed that manual methods simply cannot match, allowing for faster production times and higher levels of accuracy.

Not only does this make it easier to create complex car parts more quickly than ever before, but it also gives manufacturers greater flexibility when designing new models or modifying existing ones. The ability to rapidly prototype parts not only saves time but also ensures that any design flaws can be detected early on in the process rather than after a large amount of time has already been invested into manufacturing them.

This means automakers can develop their products faster and more efficiently while still ensuring quality control throughout the entire process. Moreover, as laser-cutting machines become increasingly sophisticated they are able to handle an ever wider variety of materials including metals, plastics, composites and even wood – making them even more versatile tools for creating complex components for automotive engineering projects.

With these powerful tools at their disposal engineers now have unprecedented levels of freedom when designing cars never seen before in history!

Conclusion

The future of automotive engineering is bright, and the introduction of laser cutting machines is playing a pivotal role in leading the way. Thunder Laser cutter is at the forefront of this technology, providing advanced solutions for high-precision cutting that are helping to revolutionize car manufacturing processes. With its powerful performance and easy integration into existing systems, laser cutting machines are allowing car engineers to take their designs to new heights while creating faster production cycles with less waste and improved efficiency.

As we continue down this path of innovation, its sure to be an exciting ride for everyone involved in the industry.