The future of automotive assembly is here, and it’s making the process more efficient and streamlined than ever before. Automated press brakes allow for faster production speeds while ensuring that the quality remains consistent.

This technology is revolutionizing the industry as traditional methods become obsolete. With these automated presses, manufacturers can produce parts with precision and accuracy every time.

Additionally, this new system requires less labor which makes it even more cost-efficient. The implementation of these machines allows for a speedier production process while still keeping up with safety standards and regulations set forth by automotive authorities.

In short, automation has made automotive assembly much easier to manage in today’s fast-paced world.

Automated Press Brakes: The Revolution in Automotive Assembly

Automated press brakes have revolutionized the way automotive assembly works. These machines are capable of quickly and accurately producing parts for vehicles at a fraction of the cost compared to manual processes.

With such impressive capabilities, it is no wonder that many automakers are turning to automated press brakes to streamline production and decrease costs. Automated press brakes allow for faster turnaround times on projects, as well as improved safety due to fewer human errors occurring during operation.

Not only do these machines increase efficiency, but they also offer greater accuracy than their manual counterparts while still maintaining quality control measures throughout the process. This makes them an ideal choice for any automotive assembly line looking for ways to reduce waste and improve productivity.

As more automakers embrace automated technologies like press brakes, we can expect a future where streamlined production becomes commonplace in automotive manufacturing plants across the globe, leading us into a new era of efficient vehicle production.

Streamlining Automotive Assembly with Robotics and AI

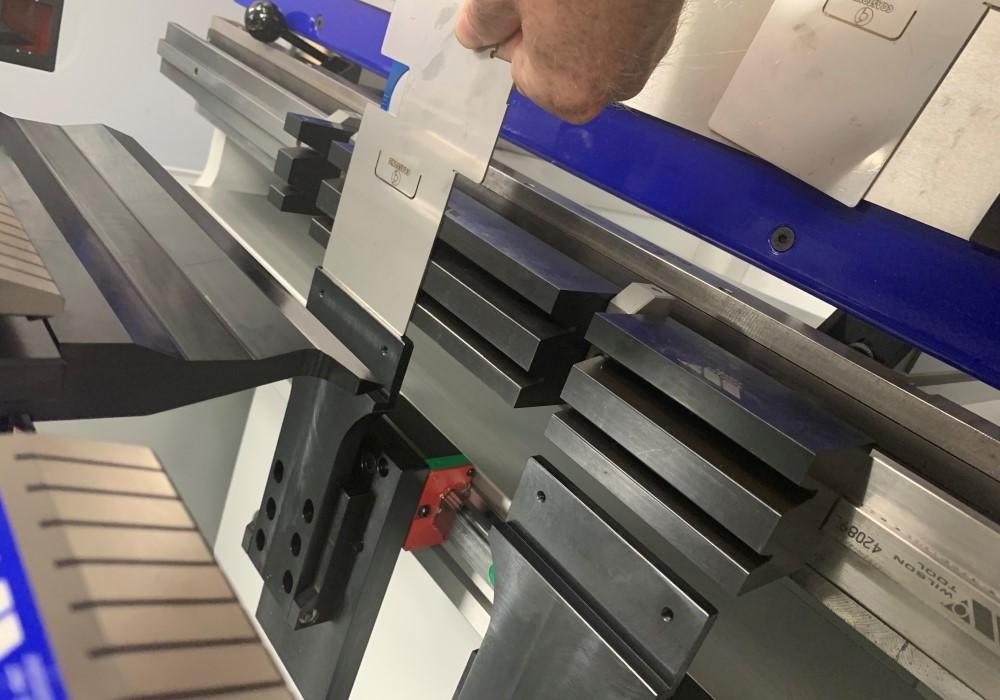

The automotive industry is rapidly changing as new technologies like robotics and AI are becoming increasingly commonplace. Automated press brakes, which use computer numerical control (CNC) to shape metal parts for cars and other vehicles, have been a game changer in the automotive assembly process. They allow manufacturers to quickly create complex shapes with precision and accuracy, streamlining production processes and reducing labor costs.

Additionally, robots can be programmed to perform many tedious tasks associated with assembly lines such as welding or riveting components together. Artificial intelligence has also improved efficiency by helping workers identify errors on the factory line before they cause costly delays or damaged materials.

As technology continues to advance, these automated systems will likely become even more efficient at streamlining auto manufacturing processes so that companies can produce higher-quality cars faster than ever before.

Implementing Advanced Technology to Enhance Efficiency

The automotive industry is rapidly evolving, and the introduction of automated press brakes and streamlined production systems is revolutionizing the way cars are assembled. With advanced technology driving efficiency in manufacturing processes, it has become increasingly possible to automate certain tasks that used to require manual labor.

Automated press brakes are capable of achieving higher levels of accuracy than ever before by using algorithms to accurately guide the cutting and bending process. Streamlined production systems help reduce waste materials while increasing output with fewer resources required for assembly operations.

By utilizing these technologies, automakers can better manage their resources while ensuring greater speed and precision throughout the entire assembly line. What’s more, these innovations can also be adapted to work with existing machinery – a major bonus for manufacturers looking for cost-effective solutions without having to invest in entirely new equipment or systems from scratch!

Shifting From Manual Labor To Automation In Auto Manufacturing

The auto industry has shifted away from manual labor to automated production processes. Automated press brakes are increasingly becoming the norm in automotive assembly, as automakers strive to streamline their manufacturing processes and reduce costs.

By replacing human labor with robots and other automation technology, automakers can improve productivity while still maintaining a high level of quality control. Automation also allows manufacturers to respond quickly to changing customer demands or unforeseen problems in the production process without sacrificing efficiency.

Robots have become an essential part of automotive assembly lines due to their ability to work at faster speeds than humans and perform tasks that require precision and accuracy every time. The use of robotic arms for welding, painting, riveting, inspection tasks, and even packaging ensures that parts meet exact specifications consistently over long periods.

Additionally, robotics allow for increased flexibility when it comes to adapting machines for different components on the same line or switching between multiple models quickly when needed. Additionally, automated press brakes play a big role in improving safety on the factory floor by eliminating dangerous manual handling activities such as lifting heavy objects or working with hazardous materials like fuel tanks or brake lines.

Press brakes also help maintain consistent product quality since they are designed specifically for each application and provide highly precise results without any operator error involved in production processes like bending sheet metal parts into predetermined shapes or angles accurately every time. Moreover, advanced AI-driven software solutions can be used throughout the entire setup process to automate repetitive tasks associated with fabricating complex parts such as mounting fixtures onto tooling plates before finalizing them into products ready for sale on shelves. Overall automation is transforming automotive assembly operations by providing safer working conditions along with greater cost savings through improved productivity across all stages of production – from design up until finished goods reach consumers’ homes – thereby opening up new opportunities within this rapidly evolving industry sector

Conclusion

The Future of Automotive Assembly is bright with automated press brakes and streamlined production. This brake press machine offers increased accuracy, faster production times, and improved safety over manual systems. Automated solutions are becoming increasingly attractive to automotive assembly companies who seek greater efficiency, cost savings, and higher quality products.

With the help of automated press brake machines, the automotive industry can continue to make strides toward making their operations even more efficient while also maintaining high levels of productivity.