The automotive industry is in the midst of a revolution, and aluminum is at the forefront. With its lightweight yet strong properties, aluminum has become an essential material for many auto manufacturers around the world, enabling them to create vehicles that are both efficient and reliable.

This article will explore how automakers have taken advantage of this versatile material and what it means for their customers. Get ready for an exciting journey into the future – one that’s powered by a metal like no other.

Aluminum: The Next Generation of Automotive Design

As the automotive industry continues to evolve, aluminum is leading the way in terms of innovation and performance. From its strength and durability to its recyclability, aluminum provides an ideal solution for car manufacturers looking to craft more efficient vehicles without sacrificing quality or style.

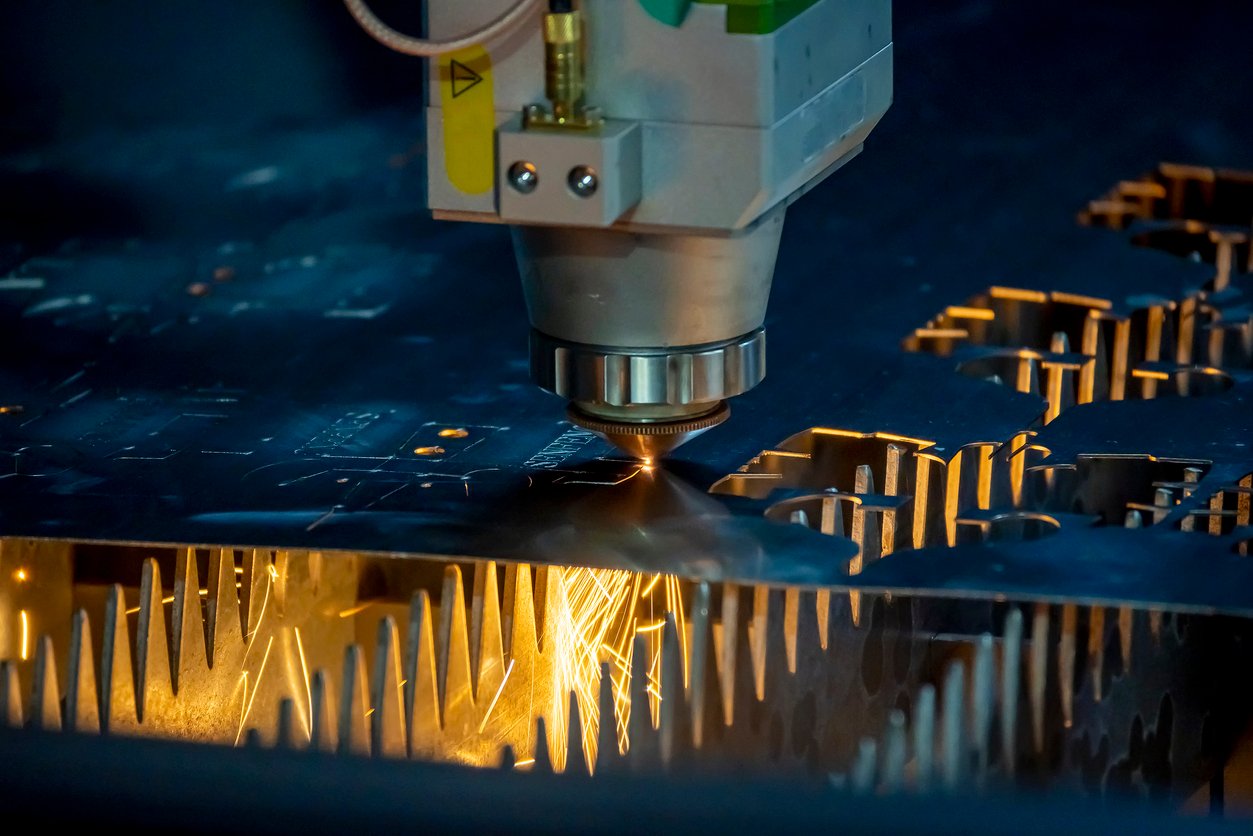

With advanced manufacturing techniques such as 3D printing and laser cutting, automakers can create intricate parts quickly and affordably with less waste than ever before.

This new generation of cars designed using lightweight materials like aluminum can reach higher speeds while consuming less fuel—allowing drivers a safe yet stylish ride that offers maximum efficiency at a lower cost than traditional steel automobiles.

Harnessing the Power of Aluminum in Automobiles

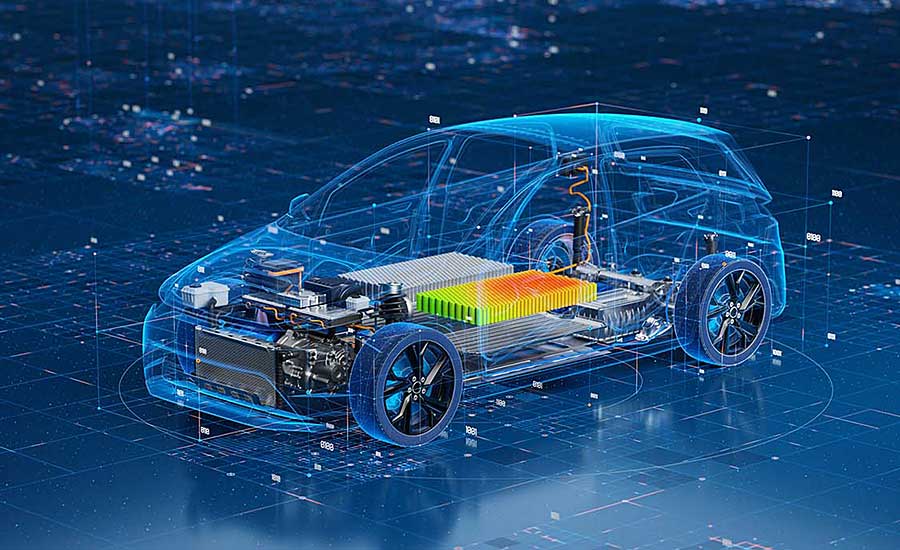

Lightweight materials such as aluminum are revolutionizing the automotive industry, allowing cars to be designed with improved performance and efficiency. Aluminum has several advantages over traditional steel in terms of its weight, strength, cost-effectiveness, and recyclability.

By harnessing the power of lightweight materials like aluminum in automobiles, manufacturers can reduce their vehicle’s overall mass while still providing superior safety and performance.

This enables them to produce lighter models that offer increased fuel economy without compromising on quality or style—making them ideal for those looking for an economical yet stylish ride.

Additionally, by using aluminum instead of steel during production processes, automakers can reduce emissions while simultaneously reducing costs associated with manufacturing and maintenance.

Ultimately, this allows drivers to enjoy a more reliable car at a lower price tag than ever before—all thanks to the transformative power of lightweight metals!

Improving Performance and Efficiency Through Innovative Design

When it comes to revolutionizing automotive design, aluminum provides unprecedented opportunities for improving performance and efficiency through innovative design.

Using aluminum instead of heavier materials such as steel or iron allows designers to create more aerodynamic vehicles that can reach higher speeds while consuming less fuel.

Additionally, the lighter weight makes cars easier to maneuver and control in tight spaces, allowing drivers greater safety on the road. Aluminum also offers superior durability than other metals, making automobiles last longer with fewer repairs over time.

With its unique combination of strength and lightness, it is an ideal material for crafting automobiles that are both powerful and efficient.

Designers today have access to a wide range of tools for leveraging the advantages provided by this versatile metal — from specialized alloys and fabrication techniques to advanced computer-aided engineering software — enabling them to create designs that maximize performance while minimizing energy consumption.

Reducing Costs and Enhancing Safety With Advanced Technology

The automotive industry is experiencing a revolution with the introduction of aluminum. By replacing traditional materials, such as steel, with lightweight and durable alloys, vehicle manufacturers can reduce costs while enhancing safety standards.

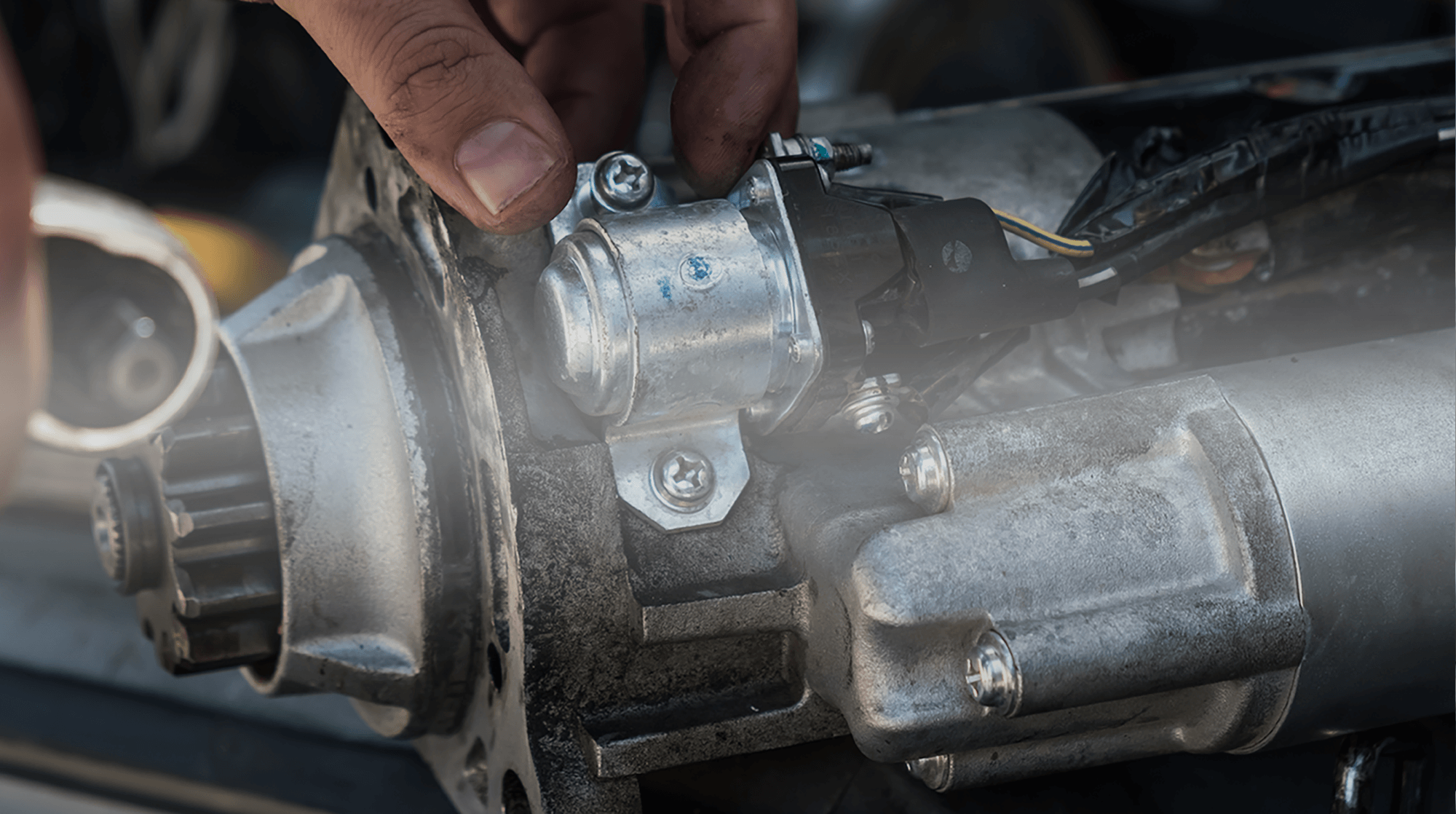

Advanced technology has been instrumental in making this switch possible, by automating production processes that would be too costly or complex for humans to manage. This automation allows for increased accuracy and precision on all levels of design and manufacturing; from car body components to intricate engine parts.

The use of state-of-the-art machines also ensures that each component meets stringent safety requirements through rigorous testing procedures. As a result, drivers can benefit from vehicles that not only cost less but offer unparalleled protection thanks to innovative advances in engineering and technology.

Driving Safely Into the Future with Aluminum Car Parts

The use of aluminum helps reduce fuel costs by decreasing the weight of vehicles, while also improving safety features such as crashworthiness and insulation.

HJ Aluminum Window & Doors has been a leader in this technology since the late 1960s, providing superior products backed by expert service and unbeatable warranties. Their experience shows why they are an industry leader in aluminum-based components used for automobiles.

With their vast knowledge base and modern production techniques, they continue to provide top-of-the-line aluminum windows & doors that meet or exceed expectations every time.