Car tires are an essential part of any car and the process of their production is complex. From concept to the road, this article takes a behind-the-scenes look at how these vital components for cars come together. Well explore the intricate details of designing, testing, and manufacturing car tires from raw materials to the finished product.

Alongside this journey we will discover the challenges posed by technological advances in production processes as well as environmental regulations that affect car tire development. Join us on a remarkable adventure into an industry that helps keep our roads safe!

Understanding the Vehicle Tire Production Process

The production of a vehicle tire is an intricate process that requires precision and skill. From concept to the road, the entire journey of creating a car tire involves several distinct steps. Each step in the process demands patience and attention to detail, as every component must be made with exact specifications.

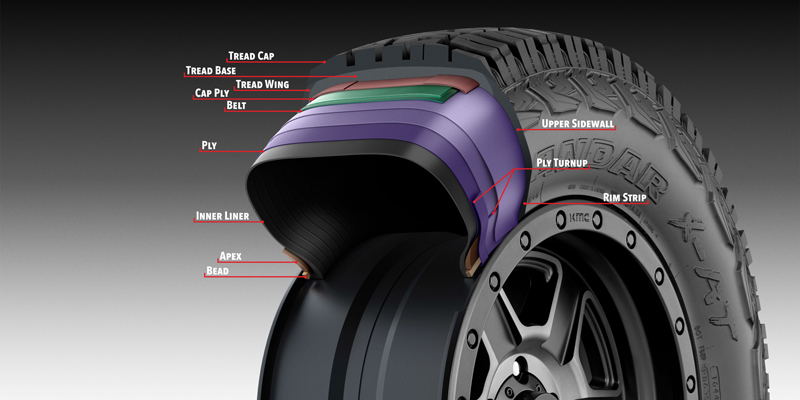

The first stage begins with the design team creating a virtual model of the desired product. Once approved by stakeholders, various components are selected for use in assembly, including rubber compound materials and chemical additives such as carbon black or silica fillers. After being formed into green tires through extrusion or calendering processes, these components are then cured under pressure inside heated molds until they take on their final shape.

In addition to this essential curing period, vulcanization is also necessary before moving on to the inspection and testing stages where strength tests such as tread wear tests ensure durability standards have been met according to regulations set forth by automotive industry professionals. Final finishing touches like balancing weights may be added at this point if needed before packaging them up for delivery or shipment directly offsite for customers’ installation needs. With thorough care taken throughout each step of the process from concept to road – it’s easy to see why producing quality car tires takes so much time but yields results worth waiting for!

Examining the Making of Car Tires from Start to Finish

From the rubber trees in the forests of Southeast Asia to a car tire on your local dealerships lot, creating car tires is an intricate process. Examining the making of car tires from start to finish reveals how much effort goes into each and every one.

The journey begins in rubber plantations, where workers harvest and process natural rubber sap that comes from tapping trees. This raw material is then transported to factories where it is combined with synthetic rubber compounds and other materials like carbon black and sulfur – resulting in what is called compound or “green” tire material. After being molded into shape, this green material undergoes an extensive curing process involving heat application until it finally turns into a finished product hardened enough for use on cars.

Further steps such as buffing and inspecting are taken before any tire can be approved for sale; only after rigorous testing will a tire make its way onto store shelves, ready for purchase by consumers around the world. From concept to road–producing car tires requires precision at each step along the way!

Breaking Down the Stages of Tire Creation

Car tires are essential components of any vehicle, ensuring safe and smooth rides. The journey from concept to finished product is a complicated one that involves numerous stages. Breaking Down the Stages of Tire Creation starts with the creation of an innovative design. This could involve creating prototypes and analyzing them for performance in various conditions before settling on a reliable version. After this, tire manufacturers use rubber compounds as raw materials for molding into shape according to the design specifications.

The rubber must be cured in large ovens before being cut into stripes and then molded onto steel or nylon cords for reinforcement – these will form the core structure of each tire. Finally, tread patterns are added along with other features such as puncture protection layers to create a complete tire ready for installation on cars!

Exploring the Engineering and Design Challenges in Producing Quality Car Tires

As the automotive industry continues to advance, car tire production has become a complex and intricate process. From concept design to road readiness, the engineering and design challenges of producing quality tires are immense. Designers must take into account factors such as wear resistance, grip performance, and fuel efficiency when creating a tire that meets the needs of modern drivers. Furthermore, engineers must ensure that these designs can be produced in an efficient manner while still adhering to strict safety regulations.

The end result is an innovative product capable of providing reliable performance throughout its life cycle. In order to achieve this goal every step in the production process must be carefully considered; from sourcing materials to final assembly line testing. This article provides insight into how manufacturers address these challenges in order to create products that meet customers’ expectations for reliability and performance on any terrain or climate condition imaginable.