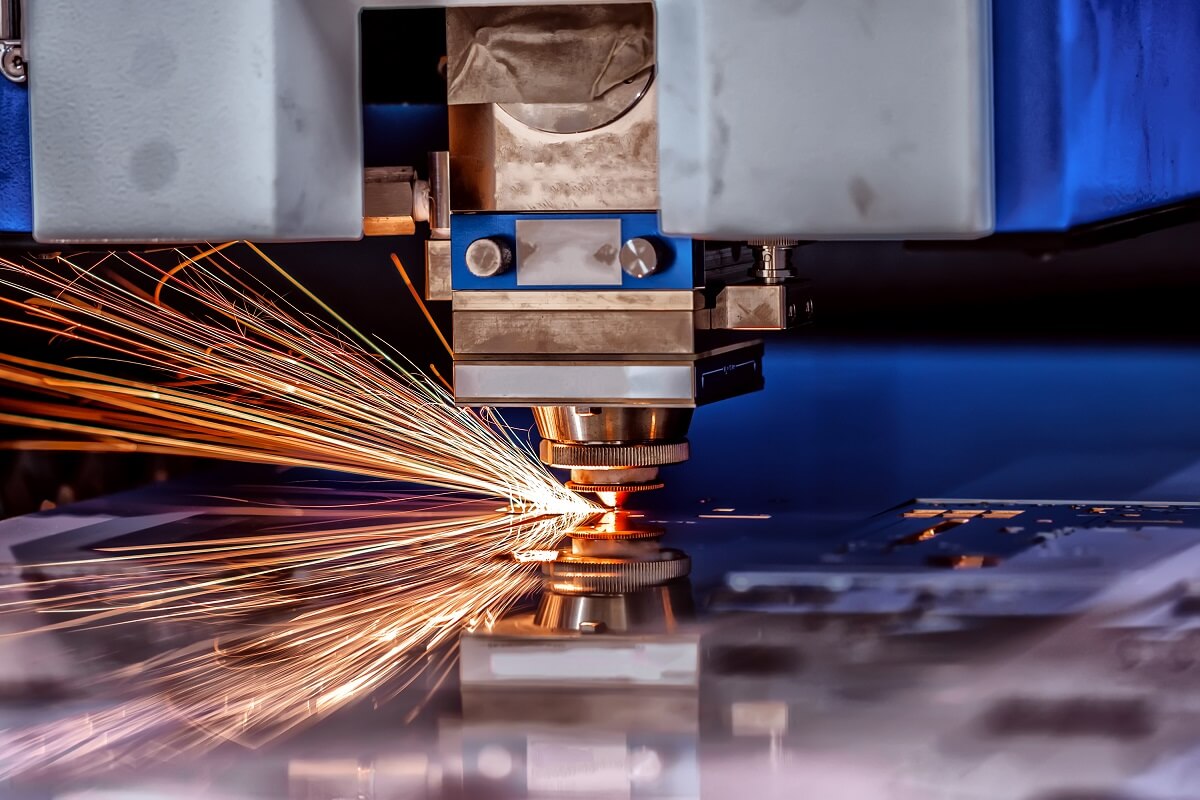

The car industry has seen a revolution in recent years, with the emergence of laser-cutting machines that are capable of achieving incredible feats. These machines have made it possible for car manufacturers to produce high-quality parts and components that require precise measurements and tolerances.

With their ability to cut through any material with great accuracy and speed, laser-cutting machines have become invaluable tools for automobile production. This article will explore the evolution of these amazing tools and examine their various applications within the automotive industry, detailing how they offer innovation at their finest.

A Brief History of Laser Cutting Machines in the Automotive Industry

Laser-cutting machines were first introduced to the automotive industry in the early 1970s. At that time, they revolutionized traditional manufacturing processes by providing an efficient and precise way of creating parts.

Over the years, laser cutting has been used for various tasks within car production such as trimming metal panels, welding components together, and even designing complex shapes with intricate detail. The technology of laser cutting has evolved significantly over the decades since its introduction.

Advances in optics have resulted in improved beam quality and increased power levels which allow faster speeds when processing materials like metals and plastics. Additionally, more robust software packages have been created that enable designers to quickly create models for their desired products with precision and accuracy.

Furthermore, new types of lasers are now available which provide greater control over the parameters of the cut while also reducing emissions from hazardous gases produced during operation. In modern times laser cutting is widely used throughout all stages of vehicle development; from prototyping designs to mass-producing components it is now possible to produce high-quality parts without compromising on efficiency or safety standards set out by regulatory bodies such as ISO 9001:2015 certification. The popularity of this method can be attributed to its ability to offer unparalleled accuracy combined with cost savings due to its quick turnaround time compared to other methods such as grinding or milling processes which require more labor-intensive operations for achieving similar results – making it a preferred option among many automotive companies today!

An Overview of Current Applications for Laser Cutting Machines within Car Manufacturing

Laser-cutting machines have become an essential tool in the car manufacturing industry. These powerful and precise tools can cut through materials with extreme accuracy, allowing for intricate designs that are impossible to achieve by manual methods.

With their ability to improve efficiency and reduce costs, laser-cutting machines have revolutionized the car manufacturing process and enabled innovation at its finest. This article will provide an overview of current applications for laser-cutting machines within car manufacturing.

From forming contours on body shells, welding together parts, creating airbags, or even fabricating entire cars – there are numerous possibilities when it comes to utilizing these versatile tools. Laser-cut metal parts can be used for a variety of purposes ranging from trim components such as door handles and window frames to more complex components such as engine blocks or suspension systems.

Additionally, laser-cut plastic pieces can be used for interior furnishings like dashboard controls or upholstery fabrics. Moreover, due to their superior precision compared to traditional cutting methods, lasers can create tiny holes inside fuel tanks which helps prevent gas leakage during driving conditions while also reducing vehicle weight – further improving overall performance and safety measures alike! Overall, the application of laser cutting technology within car manufacturing is vast yet highly specific depending on the requirements of each component being produced.

Its versatility allows it to be adapted easily; however, its power means that only experienced technicians should operate them to ensure maximum safety standards are met at all times throughout production processes – making sure that every part created meets exacting quality criteria set by today’s modern automotive manufacturers!

Examining Potential Future Uses for Lasers in the Auto Industry

The potential for lasers to revolutionize the auto industry is vast and growing. As laser-cutting machines become increasingly efficient, they are being used in a variety of ways that were not possible just a few years ago.

From accurately cutting complex shapes into car parts to welding materials together with pinpoint accuracy, lasers have already made huge leaps forward when it comes to automotive production. However, this innovation has only just begun; many more uses for lasers could potentially be explored shortly.

Laser engraving technology could be implemented on larger scales, providing vehicle manufacturers with greater control over branding or customization options for customers. 3D printing technology incorporating laser etching has also been identified as an area of potential growth; allowing car parts to be crafted with unprecedented precision in terms of size and design complexity. Overall, these advancements present exciting possibilities when it comes to improving the performance and efficiency of vehicles produced by the auto industry today – but even more so what may come tomorrow! With new technologies constantly emerging at rapid rates, they will likely see ever-increasing levels of sophistication from laser applications as time goes on – making them an invaluable asset within modern manufacturing processes worldwide.

The Impact of Innovative Laser Technologies on Automobile Design and Production

Laser technologies have revolutionized automobile design and production processes, allowing for faster and more precise manufacturing than ever before. Laser-cutting machines offer numerous advantages over traditional mechanical methods, from greater accuracy to shorter lead times.

With their ability to cut through a variety of materials with ease, laser cutters are becoming increasingly popular in automotive production lines worldwide. The impact of this innovative technology is far-reaching; it has enabled manufacturers to produce cars that are not only safer but also lighter, faster, and more fuel efficient. Companies can now create intricate parts quickly and accurately thanks to these sophisticated tools which allow for complex designs with minimal waste material.

Furthermore, laser-cutting machines have reduced labor costs while increasing productivity by allowing for quick turnaround times on large-scale projects. As automakers look towards the future, they will continue to benefit from lasers as they strive to push innovation further than before to remain competitive in an ever-changing industry landscape.

Conclusion

The introduction of Laser Cutting Machines in the Car Industry has revolutionized the way cars are designed and manufactured. From faster production times to increased accuracy, this innovative technology has demonstrated its worthiness in improving efficiency and quality.

The evolution of Laser Cutting Machines has enabled car manufacturers to cut components with precision, speed up production cycles, reduce costs, and increase customer satisfaction. As the use of laser-cutting machines continues to rise in the industry, it is clear that this technology will remain an important part of car manufacturing for years to come.