The world of technology has been revolutionized by the introduction of laser cutting machines. With their precision and accuracy, these devices are able to create intricate designs in a variety of materials with ease and efficiency.

This article takes an in-depth look at laser cutting machines, exploring how they work and the many advantages that they bring to businesses across different industries. From improving production times to reducing material waste, readers will gain insights into why these tools are so valuable today – allowing them to make more informed decisions when choosing the right machine for their needs.

Introduction to Laser Cutting Machines

Laser cutting machines are one of the most powerful precision tools available to engineers and craftsmen. They provide a unique level of accuracy and control, allowing users to create intricate shapes with flawless detail.

In this guide, well explore what laser cutting is, how it works, and how you can use it to make amazing projects. Well also take a look at the different types of laser cutters on the market today and discuss their various advantages and disadvantages. Finally, well talk about safety precautions when using these machines so that you can enjoy your work safely.

With all this information in hand, you will be well on your way to becoming an expert in laser cutting!

Understanding the Components of a Laser Cutter

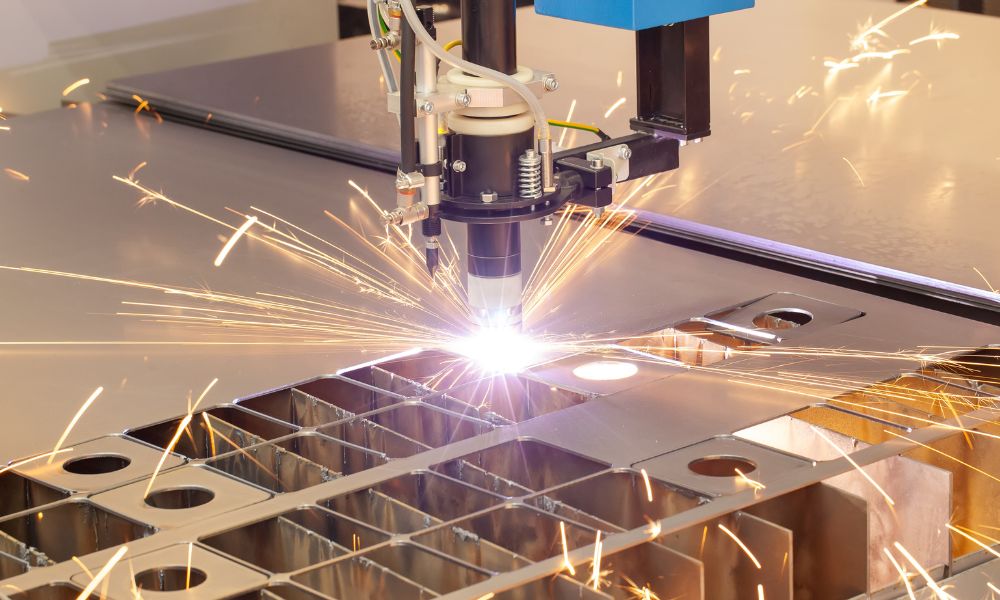

When it comes to laser cutting machines, understanding the components is key to achieving success. Laser cutters have two main parts – the power supply and the optics unit.

The power supply creates a beam of light that is focused by the optics unit into a powerful laser capable of cutting through materials such as metal or plastic with precision accuracy. It also contains other elements like mirrors, lenses, and filters that help direct and focus the energy from the power source onto a specific area on a material.

Additionally, some models may include additional components like cooling systems or air assist nozzles which help reduce heat buildup during operation or improve edge quality respectively. Finally, software programs are used to create designs for parts that need to be cut out of materials using these machines.

Understanding each components role in producing accurate results is essential for ensuring successful results when using laser cutting machinery.

Analyzing the Benefits of Precision Cutting with Lasers

Laser cutting machines have revolutionized the way materials are cut and shaped. Able to reach extreme precision, they offer a level of accuracy that other tools simply cant match.

In this in-depth guide, well explore how these innovative devices work and why they\’re so beneficial for many industries worldwide. When it comes to precision cutting with lasers, there are numerous advantages over traditional methods.

For instance, laser cutters create perfectly smooth edges with no burr or chips – something which is impossible using hand tools or saws. Lasers also possess great speed and agility; able to rapidly adjust their settings mid-cut if needed.

As such, complex shapes can be achieved quickly and accurately without any additional setup time required afterwards. Furthermore, laser cutters require minimal maintenance due to their automated nature; just periodic cleaning is necessary for optimal performance! Moreover, unlike mechanical cutting processes where heat energy tends to distort the material being worked on, lasers generate little heat when compared against other techniques – meaning thinner materials can still be handled safely without destruction of its structural integrity during cuts or engravings. This makes them perfect for delicate projects such as jewelry making or electronics assembly where intricate detail must be observed at all times! With more control over the entire process than ever before possible thanks to advanced software programs integrated into modern day machines – creating precisely crafted parts has never been easier than today!

Conclusion

Laser cutting machines are a powerful tool that have revolutionized the manufacturing industry. By using a precise beam of light to cut materials, they offer unprecedented accuracy and speed in operations.

Precision laser cutting is used in many industries including automotive, aerospace, medical device manufacturing and prototyping. With their ability to quickly create intricate designs with minimal waste material, these tools can help businesses save time and money while meeting complex production needs.

Laser cutter technology continues to evolve as new advances allow for even greater precision in cutting material faster than ever before.