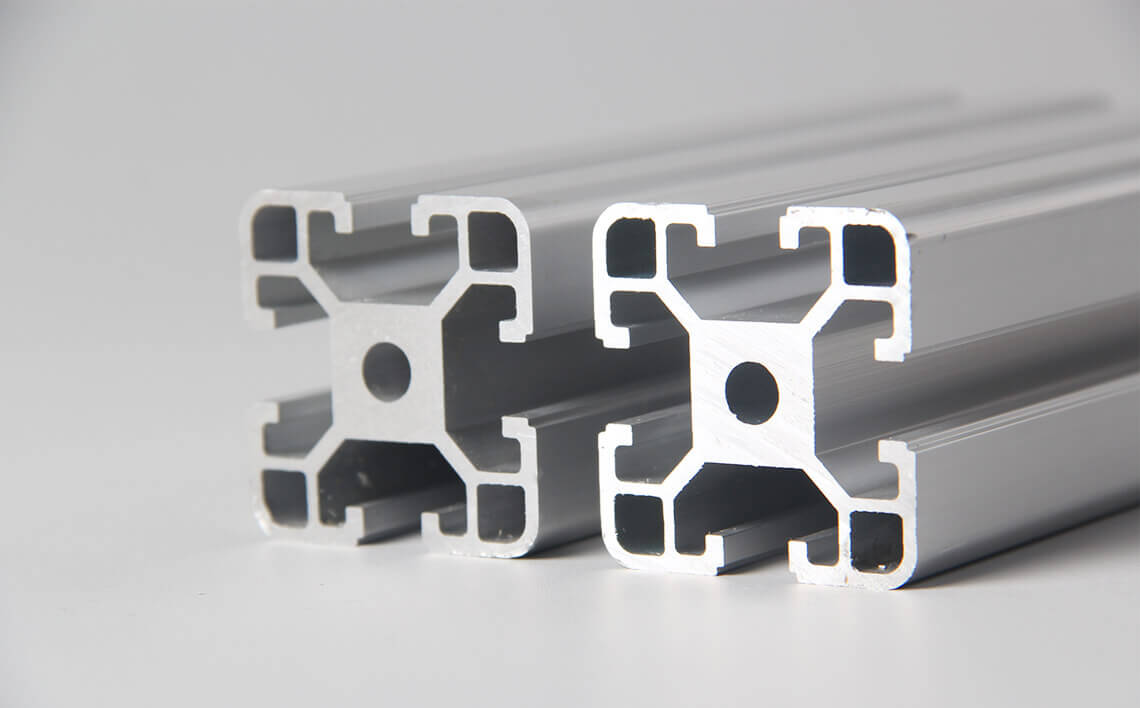

The introduction of aluminum extrusions into the trucking and trailer industries has had a major impact on efficiency. These lightweight components can provide vehicles with increased strength while still reducing overall weight, making them an ideal choice for many applications.

As advancements in manufacturing technology have enabled more complex shapes to be created from aluminum extrusions, their use in commercial trucks and trailers has grown exponentially over the past decade.

In this article, we will explore how these extruded components work together to create stronger, lighter-weight transportation solutions that can help operators reduce fuel costs while increasing performance standards.

We’ll discuss the various types of components available as well as how they interact with other elements within a vehicle’s frame or body structure. Finally, will examine some of the ways that aluminum extrusions can improve safety and increase efficiency when utilized in modern-day trucks and trailers.

Benefits of Utilizing Aluminum for Driving Efficiency

Aluminum extrusions are increasingly being used in the trucking and truck trailer industry as a way to drive efficiency. While aluminum offers many benefits, its ability to reduce weight is what allows these vehicles to achieve greater fuel economy while still providing optimum performance. Additionally, aluminum extrusion components require less maintenance due to their corrosion-resistant properties making them ideal for long-term use and cost savings over time.

Furthermore, aluminum has an excellent strength-to-weight ratio which helps in creating lighter yet stronger structures that can better withstand impacts or heavy loads during transport. These advantages all contribute towards increased driver safety and make it easier for businesses operating within this sector to maximize their profits without sacrificing quality or performance.

Cost-Benefit Analysis of Investing in Aluminum Extrusions

The cost-benefit analysis of investing in aluminum extrusions for trucks and truck trailers is an important part of driving efficiency. Aluminum extrusions are lightweight, durable, and versatile components that can be used to improve the performance of vehicles.

This makes them a great option for any transportation company looking to reduce costs while increasing fuel economy and hauling capacity. When it comes to cost-effectiveness, aluminum extrusions provide several benefits over traditional materials such as steel or wood.

They are highly resistant to corrosion which extends their lifespan significantly longer than other materials; this results in fewer replacements over time with lower associated labor costs during maintenance cycles. Additionally, they require less energy to manufacture than other materials, resulting in reduced overhead expenses from production processes and more efficient use of resources overall.

Furthermore, due to their lighter weight compared to steel or wood parts, they offer improved fuel economy when used as structural components on trucks and trailers – meaning money saved at the pump that goes straight back into your pocket! In terms of ROI (return on investment), aluminum extrusions also have a lot going for them: because they are so long-lasting it’s easy for companies who invest in them upfront to reap large rewards down the line through fewer repairs needed during ownership lifespans – not only reducing repair bills but also minimizing downtime spent out of service due scheduling repairs elsewhere. Lastly, since these parts can be produced using automated manufacturing processes means there is little need for costly human labor too – making sure you get even more bang for your buck when purchasing these items!

Conclusion

In conclusion, aluminum extrusions manufacturer provide several advantages to the trucking and trailer industries. Not only are they lightweight and corrosion-resistant but their strength-to-weight ratio makes them capable of supporting heavy loads while still providing improved fuel economy.

On top of all that, their cost-effectiveness makes them an attractive option for those looking to reduce expenses while increasing performance standards. With so many benefits, it is clear why aluminum extrusions have become increasingly popular in the transportation industry over the past decade — offering operators reliable solutions for improving efficiency without sacrificing safety or quality.